The PrevEx flammability analyzers for LEL monitoring

use the Flame Temperature Analysis (FTA) principle and consist of a whole series of models for the continuous monitoring of the concentration of combustible gases and vapors as a percentage of the lower explosive limit (LEL, LFL), primarily in industrial processes. The superior qualities of the detector and the sampling system assure the most accurate readings and highest reliability in the most demanding applications. The rugged, industry-grade design allows the installation and operation of the analyzers even in harsh environments.

- LEL monitoring of industrial processes such as solvent dryers or thermal oxidizers

- Uniform sensitivity versus different substances ensures accurate readings also for complex gas mixtures

- Online mounting in combination with a heated sampling system allows reliable, fast measurements and minimizes maintenance.

- Also available for installation outdoors or in hazardous zones

- ATEX type examination certificate includes the approval as a measurement device for explosion protection according to EN 60079-29-1 and EN 50271

- Available levels of functional safety: SIL1/SIL2 (for a single analyzer) and SIL 3 for redundant analyzers, all for low demand mode. PL d for a redundant analyzers for up to continuous demand rates.

PrevEx Analyzers are used in all industrial processes where combustible gases or vapors are released. Typical applications range from flexo to coil-coating (even ceramic kilns) to the monitoring of exhaust ducts before thermal or catalytic oxidizers in the chemical and pharmaceutical industry.

The PrevEx analyzers employ the principle of Flame Temperature Analysis (FTA). They include a carefully metered pilot, or sensing flame. The sample gas is drawn into the flame cell and any combustible components are incinerated by the flame. The temperature rise of the flame is directly translated into a reading expressed as a percentage of the lower explosive limit (% LEL/LFL). This measuring principle is unique in its uniform response towards different solvents. This unique quality can ensure accurate readings for complex or variable mixtures of flammable gases and vapors. In addition, the analyzer can also measure flammable non-hydrocarbons such as CO, NH3, H2, or H2S.

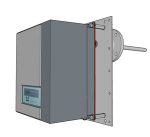

The design of the analyzers allows to install them directly on the process wall or duct. This leads to short sample lines, resulting in a quick response, and avoids typical problems with any external sampling systems.

The design of the analyzers allows to install them directly on the process wall or duct. This leads to short sample lines, resulting in a quick response, and avoids typical problems with any external sampling systems.

A concentric sample probe provides an easy way to heat the sample line even into the process, by using the hot analyzer exhaust, thus removing every possible cold spot. The analyzers can sample gas at temperatures of up to 700°C. If the temperature is higher, a ceramic probe must be employed.

All sample wetted parts are heated to avoid condensation. The temperature must be chosen to be at least as high as the dew points or flash points of the components of the sample, thus preventing condensation.

This ensures accurate readings and avoids excessive maintenance due to condensation and clogging.

Two integrated sample filters (filter elements and sinter metal filters) effectively remove particles from the sample gas. In addition, the sample train of the analyzers uses relatively large internal diameters so that slight deposits do not immediately lead to sampling problems.

The sample is drawn from the process using an aspirator, driven by compressed air. Therefore there are no moving parts in the sampling system which could fail.

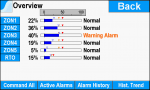

The analyzer continuously monitors the most important operating conditions. A fault is signaled when any of the following errors is detected: memory failure, loss of power, loss of temperature, loss of fuel, loss of sample flow. A fault is displayed in the display, indicated by an LED and signaled via a relay.

An additional relay signals service requests which indicate changes before a fault might be generated: The reason for the service request is indicated in the display. This can be used to schedule preventative maintenance at a convenient time without risking a malfunction.

The PrevEx analzyers can be integrated into safety-instrumented systems according to the following safety levels:

- SIL2 for a single analyzer and SIL3 for a redundant analyzer pair according to EN 61508 (Exida certificate), low demand

- Performance Level d (PL d) for a redundant analyzer pair according to EN ISO 13849-1 for up to continuous demand rates (this safety level is used for feedback control systems for the LEL concentration using the concentration reading of the analyzers, e.g. in solvent dryers according to EN 1539 or for the dynamic dilution of waste gas streams before thermal oxidizers)

The requirements set forth in the respective safety manual must be met in order to achieve the safety levels.

Data Sheet PrevEx FTA Analyzers SNR67x-Tn

| Model Numbers | SNR671-T6, SNR672-T4, SNR672-T3, SNR674-T3, SNR674-T2, SNR705-T2 | ||||||||||

| Measurement Range | 0-80% LEL/LFL | ||||||||||

| Operating Temperature | from 60°C to 250°C | ||||||||||

| Response Time |

|

||||||||||

| Messgasberührte Teile | Hard-coat aluminium, stainless steel, FKM/Kalrez | ||||||||||

| Dimensions | 406mm Height x 307mm Width x 216mm Depth | ||||||||||

| Sample gas | Dew point of sample gas and flash points of all flammable vapors must be below operating temperature. Oxygen concentration: 12%-21%Vol. (optionally 0%-21% Vol. with the option sample gas dilution option). Sampling location up to zone 1. |

||||||||||

| Options |

|

||||||||||

| Conformity | ATEX Type Examination Certificate DMT 03 ATEX G 001 X:

including measurement function according to EN 60079-29-1 and EN 50271.

|

Documents:

Accessories:

Operator panel series FTA Monitor 700 CTN for the remote control and SCADA for PrevEx FTA analyzers of the 670 series.